Exploring the Different Types of Robotic Warehouse Solutions

Introduction

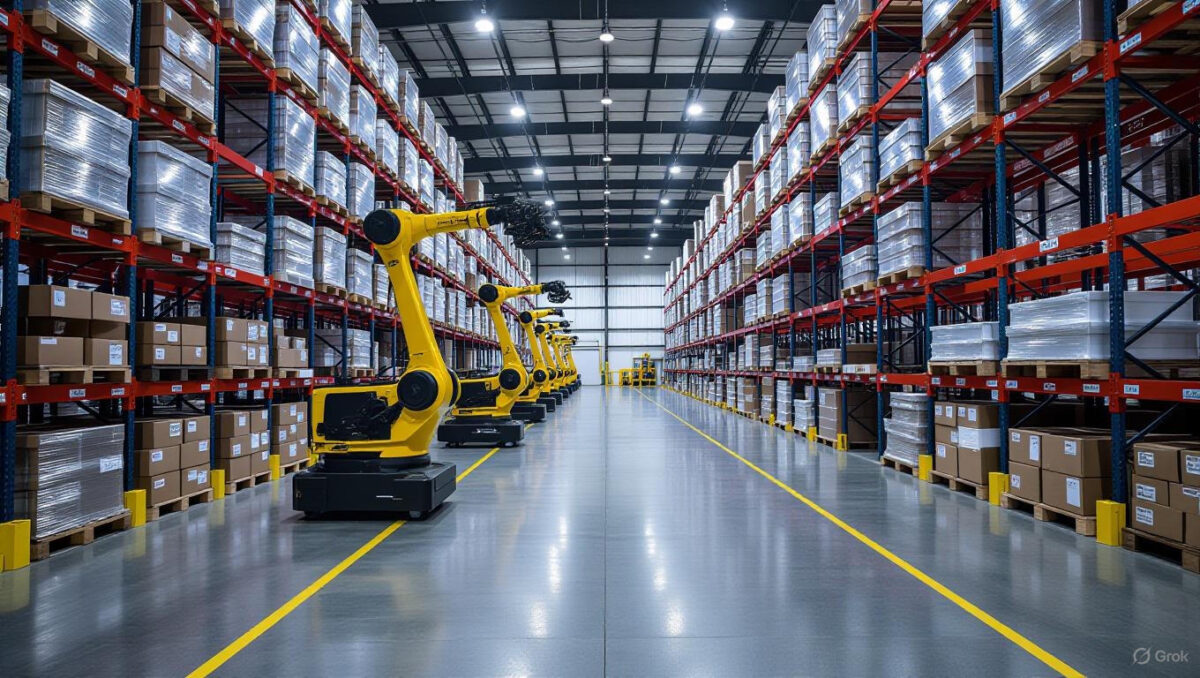

The logistics and warehousing industry is experiencing a transformative shift due to the rise of robotic warehouse solutions. These warehouse robotics systems are designed to automate various tasks, from inventory management to order picking and sorting, significantly improving warehouse efficiency and accuracy. As businesses look for ways to optimize their operations, warehouse robotics automation has become a key solution for scaling their processes and meeting customer demands.

In this blog, we will explore the different types of robotic warehouse solutions, their capabilities, and how they are shaping the future of warehouse operations. Whether you are a warehouse manager, logistics professional, or business owner, understanding these solutions is essential to improving your operations.

What Are Robotic Warehouse Solutions?

1. Defining Robotic Warehouse Solutions

Robotic warehouse solutions refer to the integration of robots and automated systems to perform tasks traditionally handled by human workers in warehouses. These systems include picking robots, automated guided vehicles (AGVs), robotic arms, and autonomous mobile robots (AMRs) that work autonomously to handle tasks like sorting, transporting, and inventory management.

The key advantage of robotic warehouse solutions is the ability to reduce human intervention, automate repetitive tasks, and enhance the speed and accuracy of operations. These solutions are designed to work seamlessly with warehouse management systems (WMS), ensuring real-time data tracking, efficient workflows, and improved order fulfillment.

Benefits:

- Increased efficiency through automation.

- Improved accuracy in picking, packing, and sorting.

- Reduced operational costs by minimizing human labor.

Types of Robotic Warehouse Solutions

2. Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) are one of the most commonly used robotic warehouse solutions. These robots are equipped with advanced navigation systems, sensors, and AI algorithms that enable them to autonomously transport goods throughout the warehouse. Unlike traditional automated guided vehicles (AGVs), which follow fixed paths, AMRs can navigate dynamically and adapt to changes in their environment, making them highly flexible.

AMRs are used for tasks such as material transport, moving goods from one location to another, and delivering products to picking stations or sorting areas. These robots can work alongside other warehouse robots and are ideal for environments where goods need to be moved quickly and efficiently.

Benefits:

- Flexible navigation with autonomous decision-making.

- Reduced traffic congestion and better space utilization in warehouses.

- Increased throughput with continuous operation.

3. Robotic Arms for Picking and Sorting

Robotic arms are specialized robots used for picking and sorting products in warehouses. These robots are equipped with gripping tools and AI-powered vision systems, allowing them to pick up, sort, and place items on shelves or conveyors. Robotic arms are particularly effective for handling items of various shapes, sizes, and weights.

Warehouse robotic systems that include robotic arms can automate the order picking process, reducing human error and increasing the speed at which products are retrieved. These systems are often used in conjunction with other automated systems to create a seamless sorting and packing process.

Benefits:

- High precision in picking and sorting.

- Adaptability to handle different types of products.

- Increased efficiency and faster order fulfillment.

4. Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) are another essential component of warehouse automation robotics. AGVs are robots designed to move materials through the warehouse, following predefined paths or tracks. They are commonly used for transporting goods from one location to another, such as from receiving areas to sorting zones or from storage shelves to packing stations.

While AGVs follow fixed paths, they are still capable of performing tasks autonomously and can be integrated with other robotic systems to create more complex workflows. AGVs are particularly useful in warehouses where the movement of goods is highly structured and predictable.

Benefits:

- Efficient material transport within structured environments.

- Continuous operation without the need for human intervention.

- Cost-effective automation for material handling.

5. Collaborative Robots (Cobots)

Collaborative robots (or cobots) are designed to work alongside human workers in the warehouse. Unlike traditional robots, which operate independently, cobots are built to assist human workers by handling tasks that are repetitive or physically demanding. They are equipped with sensors that allow them to work safely in close proximity to humans.

Cobots are particularly useful in tasks that require a combination of human decision-making and robotic precision. For example, cobots can be used for picking, sorting, and packing products, working alongside human workers to improve speed and efficiency. These robots are easy to deploy, user-friendly, and adaptable to various tasks.

Benefits:

- Improved collaboration between humans and robots.

- Increased productivity with shared tasks.

- Enhanced safety in warehouse environments.

6. Robotic Picking Systems

Robotic picking systems are designed to automate the picking process in warehouses. These systems typically consist of robotic arms, vision systems, and grippers that work together to identify, select, and pick products from shelves. Robotic picking systems are often integrated with other warehouse automation systems to transport the picked items to sorting or packing stations.

These systems can improve order accuracy, reduce human error, and increase picking speed, especially in high-demand environments where quick and precise order fulfillment is crucial. Robotic picking systems can also work with AI and machine learning to continuously optimize and refine their picking strategies.

Benefits:

- Faster picking and reduced order errors.

- Higher throughput in high-volume warehouses.

- Greater efficiency with AI-powered decision-making.

The Impact of Robotic Warehouse Solutions on Efficiency

7. Enhancing Operational Efficiency

The introduction of robotic warehouse solutions is significantly improving warehouse efficiency. By automating tasks like sorting, picking, and transporting, robots are able to perform these tasks faster and more accurately than human workers. This not only speeds up the order fulfillment process but also reduces the risk of human error, improving overall warehouse productivity.

Warehouse robotics automation helps businesses achieve greater scalability, allowing them to meet rising customer demand without adding more labor. Robots work continuously, without the need for breaks, making them ideal for 24/7 warehouse operations.

Benefits:

- Non-stop operation with robots working around the clock.

- Reduced labor costs through automation.

- Increased scalability for growing operations.

8. Reducing Human Labor and Costs

By implementing robotic warehouse solutions, businesses can reduce their reliance on manual labor for routine tasks. Automation not only reduces labor costs but also frees up human workers to focus on more complex or higher-value tasks. For example, robots in warehouse systems can handle repetitive and physically demanding tasks like inventory transport or order picking, while human workers can focus on tasks that require more judgment or decision-making.

The reduction in human labor also minimizes the risk of work-related injuries, as robots take over dangerous tasks, ensuring a safer work environment.

Benefits:

- Lower labor costs due to automation.

- Reduced physical strain on human workers.

- Safer working conditions with robots performing hazardous tasks.

Conclusion

Robotic warehouse solutions are revolutionizing the way warehouses operate, making them faster, more accurate, and more efficient. From autonomous mobile robots (AMRs) to robotic arms and collaborative robots (cobots), the various types of warehouse robots are streamlining material handling processes, enhancing order fulfillment, and reducing operational costs.

As robotic warehouse systems continue to evolve, they will become even more integral to the logistics and supply chain industries. Businesses that embrace warehouse robotics automation will be able to meet growing customer demands, scale their operations, and remain competitive in the fast-paced e-commerce world.

Start Implementing Robotic Warehouse Solutions Today

Ready to improve your warehouse operations with robotic warehouse solutions? Subscribe to our newsletter for the latest updates on warehouse robotics, automation technologies, and how robots in warehouses can optimize your logistics operations. Or download our free guide to learn how to integrate robotic systems into your warehouse today!