Your Complete Guide to Warehouse Picker Robots

Warehouse robots have gained enough importance in distribution centres, supply chains, and warehouses where order automation is necessary. There are several types of warehouse robots found in the market. However, choosing the one that best suits the company’s needs no matter the sector, is significant. In the digital and IT world, where businesses strive for better and greater competitiveness, 90% of organizations avail themselves of robotic systems. They all have varying functionalities and forms. As per the recent reports of IT consulting company Logistics IQ, every warehouse should need to have picker robots that can easily maintain annual growth of up to 15% until 2023. Nowadays, order picking robots rely on the top of the IT market, which is helpful for all warehouse owners.

However, warehouse picking robotics are different from the common machine robots. They aim to automate their warehouse picking tasks and bring ease and convenience to all manufacturers’ businesses. Warehouse robot pickers manage dozens of picking functions in one go and automate warehouse repetitive picking processes. The modern innovation of robots aims to upgrade operations and make them more efficient. Thus, they reduce additional costs because they entirely automate all kinds of warehouse tasks. We will explore that what is the working of these warehouse picking robots and how they can help companies to automate their routine tasks.

What are Warehouse Picker Robots?

Warehouse picker robots are the latest order picking machines that can perform the order picking task in any industry. They work in a programmatic and automated way. It shows that they follow all the algorithms and instructions to pick all kinds of orders without guidance. This sort of operation can open up many possibilities for all kinds of warehouse businesses to expand their order picking and packing capabilities.

The businesses can overcome their entire cost of hiring labor. The reason is that all these kinds of order picking tasks will be performed by robot pickers. Through this phase, the companies can upgrade their overall order picking process in a more efficient way. Warehouse picker robots are available in many forms. One of the simplest examples is the traditional robots, which are integrated in the form of mobile robots that can fully automate all storage in computer systems. Ultimately, all kinds of automated picker robots get into the hands of business flexibility.

Which Industries Can Use Warehouse Robotic Picker Machines?

Nowadays, with the advancement of AI in almost every field, the use of warehouse picking machines in the form of robots is nearly found in every industry. They are capable of enhancing warehouse operations in almost every manufacturing field.

Businesses can avail of a range of opportunities to automate their business with the use of robotic pickers. The automation of all the complex tasks will bring ease and convenience. Automatic tasks upgrade the warehousing operations that were considered more expensive and complex in the past. Those industries that can use these warehouse picking machines include the following:

- Industrial business components

- Retailing work

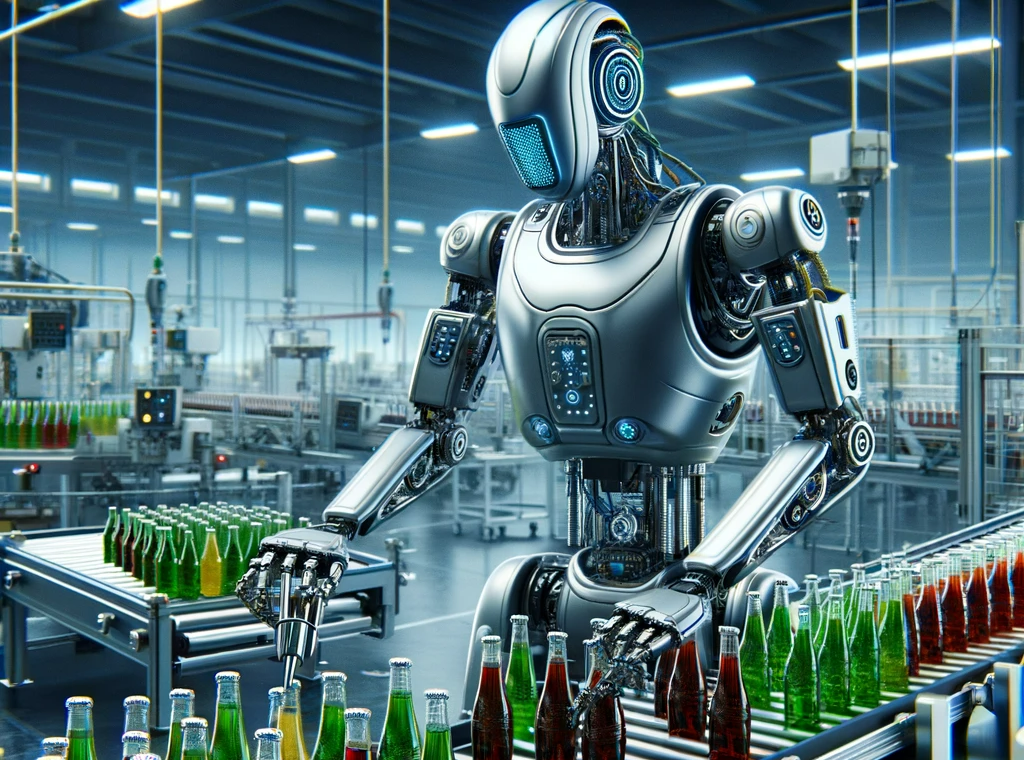

- Beverages and food

- 3rd party integrated operations

- Pharmaceutical operations

How Can Robotic Warehouse Picking Machine Works?

As we mentioned, there are many types of warehouse picker robots available in the market. However, every business can choose any type of order picking machine that can collaborate with their business processes. The most common type of robot warehouse picking system is INVIA robotics. But how do they work? Basically, this kind of automated picker robot is designed to help all those warehouse businesses automate their entire picking system and save the additional cost of hiring labour.

Nowadays, every international and multinational warehouse rely on these kinds of machines, such as automated storage, picker robots, conveyors, automated shuttles, and retrieval system. This kind of automated system can eliminate the need to hire hundreds of laborers. Also, these kinds of solutions are versatile enough to go with modern alternatives. Basically, these warehouses picking automation robots integrate with the directed workflow approach.

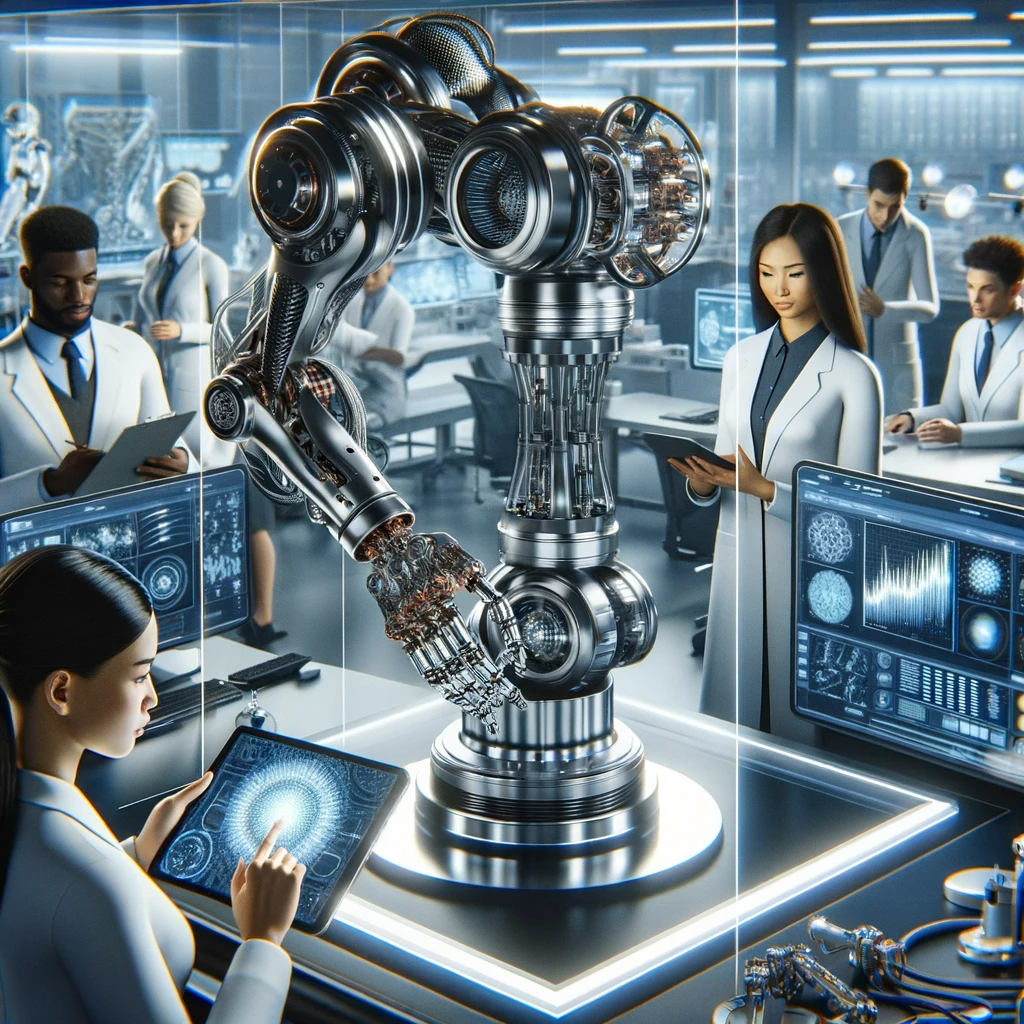

Many AI algorithms combine together to associate with these collaborative robots. These robots follow the algorithms that are inserted in their integration. Also, they follow the same integral steps that normal or manual picking methods include. Fortunately, they work without the inefficiency of human errors, which can arise at the time of order processing.

Explore Major Types of Warehouse Picker Robots

There is a wide variety of warehouse picker robots available in the market. They all are based upon specific robotic solutions that work under a broad range of requirements dedicated to special work. You can find a flexible solution to simple ones that can handle all kinds of order picking tasks. However, these machinery are designed and uniquely built for dedicated order picking processes. But you can explore all the major types of order picking robots that can perform automated tasks in an efficient manner.

Before investing in any robot picking machine, you should specify your requirements to get an optimized solution:

1. AR or AS Robot Systems

AR or AS Robotic systems are comprised of a wide collection of retrieval or automated storage robots. There are many kinds of AR systems available in the market. Some of the examples of these systems include:

- Mini-loader system

- Auto storing system

- Automatic forklift machine

- Overhead AR and AS robots

Basically, they are considered a large solution for all those industries that are looking for automated order picking robots. They include hybrid machines that work for businesses and private solutions. AS and AR systems are highly adaptable and scalable. They are often manufactured upon specifications that depend on customer requirements for any business.

These systems provide business manufacturers with feasibility and a high level of customization to connect with demanding applications. They can even combine with many other order picking solutions to make robotic piece picking machinery.

2. Mobile Picking Robots

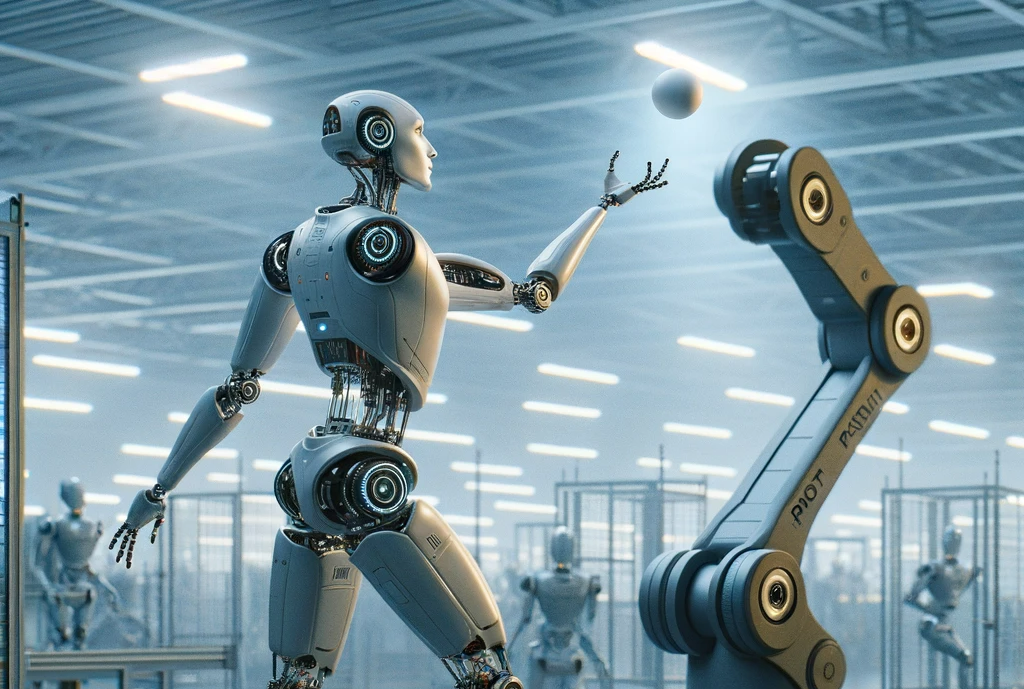

Let me talk about autonomous pickers. The most popular machinery that comes in front of us is a mobile picking robot. This kind of robot includes many variations of real robotic arms that are mounted on the applications used for mobile automation. Basically, these picker robots can traverse all the business products to the destination at which the robotic arm will pick up the product from the shelf or the bin and place it in the required position.

Basically, they work under the latest cutting-edge technologies, such as artificial intelligence and machine learning. They work like a human and cut off the need to hire more helpers in warehouses. The most common mobile picking robot uses a 6-axis composition to perform all the robotic picker tasks. Comparatively, on the high skill level, some organizations customize these robots for up to 12 axes robotic machines, which are based on AR and AS machinery.

Advantages of Using Robotic Warehouse Picker Machines

There are many amazing benefits of using a robotic picking system on an industrial level. But let’s discuss and take a look at the deep insights and impactful benefits of using picking robots in warehouses.

1. Easy to Learn

One of the top-most benefits of using Order Picker in the business warehouse is that they can easily adopt the changes you made in task performance. These systems can learn new tactics and processes within a few minutes. It means that you don’t need to instruct them and give them a few months to have expertise in your business task. It means that they can easily adopt the new technologies and collaborate with the high-tech instructions.

2. Super Intelligent Productivity

Robotic warehouse pickers are known to automate all the ordered picking tasks within a few minutes. Just like the order picking rewards, mobile automated picking machines use high-technology solutions to decrease the picking time. At the most advanced level, some companies use collaborative robots that can speed up the process of order picking by roughly two times. The biggest benefit that many companies offer is that they can the form all day long without the need for any break or changing their shifts.

3. Quick Implementation

One of the key benefits of using shelf picker robots is that they can adopt and perform quick implementation of new technologies. They can be the best investment for those warehouses that are producing products on a large scale and need to invest less money in Labor. They can see the amazing benefits of using robotic warehouse pickers within two to four weeks.

4. Flexibility and Safety

Robot picking machines and mobile technologies meet ANSI and OSHA Standards. Some warehouse picking reports use advanced technologies, and some of them rely on simple sensor technology tools. They can be the safest replacement for humans. They also provide the benefits of working in a safe environment and reduce the chances of job accidents and health injuries. Also, they are flexible enough to connect with modern automation technologies and combine them with different collaborative robots to provide more advanced solutions.

5. Adapting to Current WMS Systems

In the past, warehouses invested huge amounts of money in upgrading their physical infrastructure. That can be a more costly option as compared to investing in a robot warehouse picking system. The reason is that these collaborative robots will not require any sort of additional maintenance cost that is performed on the side of IT. They can easily adapt to your system requirements and even combine with other collaborative tools to enhance your business work.

6. Scalability

In the past, 90% of warehouse owners used traditional ways for their automation solution. However, in the past few years, with the advancement of robot picking tools and machinery, warehouses can perform their task without any interruption. They can upgrade the new algorithms anytime between their business work. This will shift all the disruption that happened in past seasonal approaches.

7. Lower Investment Options

As we all know, robotic order picking machines are famous everywhere around the world, although the latest robotic order picking machines have become so much more prominent in the market. But as compared to the traditional methods in which companies need to hire thousands of laborers and helpers to perform a routine task, investing in the warehouse picking robot requires low investment. However, the inventors of this technology state that the overall price tag of these warehouse picking automation machines is the 5th portion of the traditional automation system that we all used in the past.

Using the Latest Warehouse Picker Machines

Integrating and selecting the robotic order picking machine is a tough task. There are several steps that you need to consider, and they help you out in making a decision to invest in this machinery. Before investing in a robot picking warehouse machine, you need to understand how it works, which helps you to avoid future issues.

First of all, you need to define your business needs. You need to clarify what sort of processes you need to automate in your warehouse. What sort of goals you would like to achieve? What is your plan in return for investment? These are some of the questions that you need to ask yourself before investing in a light-out warehouse machine. Whether you need a mobile picking robot or an order picking robot, this discussion is entirely based upon your required outcome. You need to specify these things, including the following:

- Machine weight

- Order picking speed

- Machine texture, size, and work type

- Required outcomes

- The budget allocates for the entire project

All of the above-mentioned metrics will help you know which kind of pickers warehouse machine robots perfectly suit your needs. If you state all these factors, you will make sure to have a successful business process implementation in the future.

The Bottom Line

Nowadays, many warehouses come along with AI technologies to facilitate their order processing tasks. Those businesses that have a large number of order processing tasks can easily automate their order picking processes with the use of warehouse picker robots. Automation and robotics combined with each other to provide advanced solutions that can upgrade your business effectiveness and credibility.

The advanced picker machine warehouse technologies can facilitate all business processes in a more efficient way. Automatic order processing and picking robots create the facility to achieve a high volume of business orders that are unable to be achieved with the use of traditional processes. With the advancement of new technology tools and AI, these systems can minimize the additional cost. It would help new businesses to upgrade their profit by up to 6X times.