How Do Warehouse Robots Communicate with the Cloud?

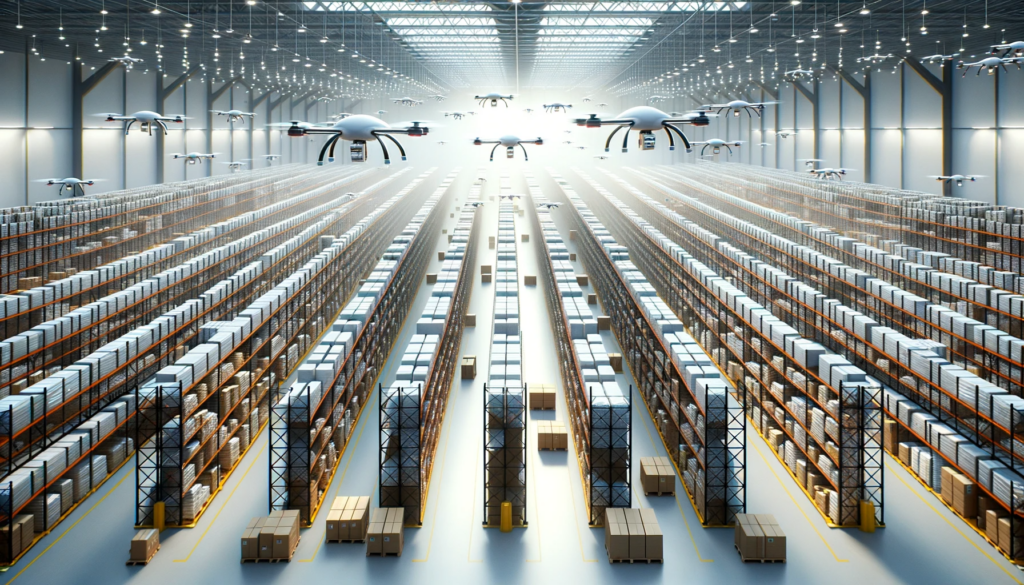

Robots used in warehouses have changed the world of various industries, such as logistics and supply chain management. Shaping modern businesses with a scalable, efficient, and cost-effective solution regarding their storage and retrieval needs. Among the most phenomenal capabilities of warehouse robots is their ability to communicate with the cloud.

The synergy between robots and clouds has brought about a new era of warehouse management practices. In this article, you will take a deep dive into the world of robotics and their connectivity to the internet that shows how warehouse robots communicate with the cloud.

What are Cloud Connected Warehouse Robots?

Cloud communicating robots, cloud robotics, are the idea of robots communicating with the cloud, allowing them to access and share data in large amounts. The collaboration of physical automation and robots’ digital capabilities changes how goods are stored, picked, packed, and shipped.

Robots and artificial intelligence are usually equipped with advanced sensors, cameras, complex data processing algorithms, and the ability to communicate with remote servers and databases.

However, this communication via the Internet makes data exchange and analysis possible in real time. The integration with the cloud amplifies robots’ abilities, making them significantly more advanced than traditional robots.

In terms of benefits, the involvement of cloud-connected robots in warehouses can do the following things:

- Reduce operational costs

- Improve the accuracy of tasks being conducted

- Ensure an atmosphere of a safe workplace

- Aid in decisive decision making by providing valuable insights

These robots alter the way a warehouse functions, allowing them to adapt to the continuously shifting domain of eCommerce.

Need for Cloud Communication in Warehouses

The need for cloud communicating robots in warehouses is evident as businesses aim to optimize and automate their operations to compete with their competitors. Cloud communication becomes essential to match the demands for efficiency, accuracy, and adaptability of a company that enables warehouses to interact with the cloud, benefiting businesses in various ways.

1. Real Time Access

Cloud communication in warehouses provides real-time access to data and resources. This accessibility empowers warehouse managers to make informed decisions quickly, enhancing operational efficiency. By utilizing cloud-connected systems, managers can monitor and adjust:

- Inventory levels

- Track the movement of goods

- Staffing and resources in response to shifting demand

In addition, the dynamic use of the cloud’s data-driven abilities significantly reduces the risk of stockouts, overstocking, and inefficient allocation of resources.

2. Improved Collaboration

Cloud communication enhances connectivity and collaboration among different components of the supply chain. Warehouse robots can communicate with cloud servers, which, in turn, can interact with other systems, such as transportation management software, suppliers, and retailers.

This interconnectedness allows the flow of goods from manufacturing to delivery, reducing delays and errors. It enables businesses to adopt just-in-time inventory practices, minimizing carrying costs and improving overall supply chain agility.

A Breakthrough in Wireless Technologies

Wireless technologies are the lifeline of modern warehouse robots, serving as the backbone for communication and control within the automated systems of a warehouse. These technologies enable warehouse robots to operate in dynamic environments, facilitating real-time data exchange and coordination.

Wireless Connections

Wireless connections such as Wi-Fi networks, Bluetooth connections, radio frequency identification, and cellular communication ensure warehouse robots remain agile and responsive. Thereby, these technologies support the robots’ ability to navigate warehouses efficiently while enabling them to:

- Relay essential data to cloud-based systems for inventory management

- Enhancing the overall productivity of warehouse operations

- Performance optimization

- Predictive maintenance

Warehouse Flexibility

The flexibility to adapt to diverse warehouse layouts and operational needs is also aided by wireless technologies. Robots can communicate with each other with centralized control systems and cloud-based servers, performing tasks like inventory tracking, picking, packing, and replenishment. Without physical tethering, robots can navigate the warehouse environment more freely, avoiding obstacles and dynamically adjusting their routes as necessary.

Some of the Common Cloud Communication Protocols

Cloud communication protocols are the protocols that enable robots to communicate and maintain interaction with the cloud. These protocols serve as the language that ensures data synchronization, enhancing warehouse operations and overall effectiveness.

Here are some of the commonly used cloud communication protocols.

1. HTTP

HTTP, Hypertext Transfer Protocol, allows for data transmission across the internet. The same protocol also powers the World Wide Web (WWW).

In warehousing, HTTP facilitates the transfer of information between cloud servers and robots, enabling real-time updates and commands. This protocol is particularly suitable for applications that require reliable, bi-directional communication, such as updating inventory levels and issuing orders to warehouse robots.

2. MQTT

MQTT, Message Queuing Telemetry Transport, is a lightweight publish-subscribe protocol designed for low-bandwidth, high-latency, or unreliable networks. MQTT is instrumental in ensuring efficient and reliable communication between cloud servers and robots in warehousing. It minimizes bandwidth consumption and is well-suited for monitoring sensor data and sending notifications, making it a valuable choice for applications where network constraints are considered.

3. CoAP

CoAP, a Constrained Application Protocol, is an IoT-specific protocol for resource-constrained devices. In the warehousing context, CoAP is employed when robots and sensors have limited processing power and memory. CoAP optimizes the exchange of information, making it a valuable protocol for managing and monitoring small, resource-constrained devices while maintaining low power consumption.

4. AMQP

AMQP, Advanced Message Queuing Protocol, is a widely adopted open-standard messaging protocol designed for efficient and reliable communication between various applications and systems. In warehouses, AMQP is used for real-time communication and coordination between components, such as robots, sensors, and inventory management systems. It facilitates the transmission of critical data related to inventory levels, order status, and equipment maintenance, enhancing operational responsiveness.

Security and Privacy Measures in Warehouse Robotics

Securing sensitive and crucial information for any business is a significant concern. Robots and other connected devices play an increasingly central role in warehouse operations, so a robust security framework is necessary to protect the system against potential threats and data breaches.

1. Data Encryption

Implementing end-to-end data encryption is a fundamental security measure. This ensures that data transmitted between warehouse robots, sensors, and the cloud is scrambled and can only be deciphered by authorized parties. Encryption protocols help safeguard the integrity of the data during transit.

2. Secure Authentication

Mechanisms for authentications are essential to verify the identity of both robots and human operators accessing the system. Multi-factor authentication (MFA) can add an extra layer of security, ensuring that only authorized personnel can control and interact with the robots and cloud infrastructure.

3. Access Control

Access control mechanisms restrict access to data and systems on a need-to-know basis. It ensures that only authorized users can access specific data and functionalities. By setting access controls, organizations can minimize the risk of unauthorized access.

4. Regular Software Updates

Keeping robot software and cloud platforms up-to-date with the latest security patches and updates is crucial. Vulnerabilities can emerge over time, and regular updates help prevent potential risks and maintain a secure environment.

5. Physical Security

Physical security measures within warehouses are equally important. Access to the robots, control systems, and data centres should be restricted, and surveillance systems can help deter unauthorized access.

What are the Advantages of Cloud Connectivity?

The use of robots in warehouses provides numerous benefits for warehouses, and these benefits are further amplified if the robots can communicate with the cloud. These benefits allow warehouses to effectively and efficiently complete their operations and match the eCommerce market’s demands.

1. Real Time Visibility

Cloud based warehouse management systems provide real-time visibility into inventory levels, order status, and warehouse operations. This enables accurate decision making and responsive actions, reducing the risk of stockouts, overstocking, and operational bottlenecks.

2. Scalability

Cloud solutions feature high scalability, which allows businesses to adapt to changing demands without significant upfront investments. Warehouse operations can expand or contract as needed, accommodating seasonal fluctuations or unexpected changes in market conditions.

3. Accessibility

Cloud-based systems can be accessed from anywhere via the Internet, facilitating remote monitoring and collaboration. Warehouse managers, suppliers, and other stakeholders can easily access and update data, improving communication and coordination.

4. Cost Efficiency

Solutions based on the cloud reduce the need for on-premises hardware and maintenance, lowering operational costs. Businesses can also pay for services on a subscription basis, which can be more cost-effective and predictable than traditional software licenses.

5. Enhanced Security

Cloud providers often invest significant amounts considering security measures, including data encryption, redundancy, and backup systems. This can offer more data protection than on-site solutions, reducing the risk of data loss or breaches.

6. Automation

Cloud connectivity facilitates the integration of warehouse management systems with other business applications, such as eCommerce platforms and transportation management systems. Automation of routine tasks and data sharing streamlines operations and reduces manual errors.

Robot to Cloud Communication Hurdles

While it is true that cloud robotics provide various benefits to warehouses, several hurdles need to be overcome to have an efficient and smooth procedure of operations.

Latency

The delay between data transmission from robots to the cloud and receiving responses can be critical in real time applications. High latency can impact the responsiveness of robots and delay essential decision making processes. The optimization of data transfer protocols and selecting the proper cloud infrastructure with low latency can be crucial in overcoming this challenge.

Bandwidth and Connectivity

Warehouse robots often operate in environments with limited network connectivity. Maintaining consistent communication could be better when the network connection is unstable or weak. Implementing robust wireless technologies, such as redundancy and failover mechanisms, helps ensure uninterrupted contact.

Data Security and Safety

Protecting the data transmitted between robots and the cloud is a top concern for businesses to prevent data breaches. Security vulnerabilities upon exploitation can compromise both operational integrity and sensitive information. Safety methods like encryption, secure authentication mechanisms, and continuous monitoring for potential threats are necessary to safeguard data and system integrity.

Scalable Features

As the number of robots in a warehouse grows, the communication infrastructure must be able to scale accordingly. The challenge lies in ensuring that the system can efficiently manage a high volume of data from multiple robots without compromising performance. Cloud solutions offering scalability and load balancing features can mitigate this challenge.

Data Management

Managing the vast amounts of data generated by warehouse robots can be complex. Efficient storage, retrieval, and analysis of this data require careful planning and robust data management systems. Cloud-based solutions that include data analytics and machine learning capabilities can assist in deriving actionable insights from the data.

Cost and ROI

The deployment and maintenance of a robot to cloud communication infrastructure can be cost-intensive. It’s essential to carefully evaluate the return on investment (ROI) and ensure that the benefits, such as improved efficiency, justify the associated expenses.

Upcoming Trends in Cloud Connected Warehouse Robotics

The domain of cloud connected warehouse robots is improving and evolving quickly, and the future seems promising. A prominent upcoming trend is the growing integration of artificial intelligence and machine learning into these systems.

Warehouse robots are becoming increasingly capable of autonomously adapting to changing conditions, optimizing paths, and making real-time decisions based on the data they collect. This enhanced intelligence improves efficiency while opening the door to predictive maintenance, as robots can monitor their health and request repairs before issues lead to downtime.

Another noteworthy trend is the expansion of collaborative robotics, where human workers and robots work side by side. These “cobots” are designed to augment human capabilities, offering assistance in physically demanding or repetitive tasks. Cloud connectivity ensures that these collaborative systems can be easily controlled and monitored, even from remote locations, enhancing the overall flexibility and adaptability of the workforce.

The emergence of 5G connectivity will bolster cloud-connected warehouse robotics’ capabilities further, providing ultra-low latency, high bandwidth, and enhanced reliability, making real-time data exchange and remote control even more effective.

Conclusion

Integrating cloud connectivity into warehouse robotics is bringing about a new supply chain efficiency and adaptability era. These technological advancements, driven by real-time data exchange, intelligent decision-making, and collaborative robotics, enhance operational responsiveness, reduce costs, and ensure that warehouses remain agile in the face of constantly fluctuating market demands.

As cloud connected warehouse robotics evolve, they offer a promising path toward a future where logistics and inventory management are more dynamic, efficient, and responsive, benefiting businesses and consumers alike in the dynamic landscape of the modern supply chain.