Is Your Warehouse Robotics Program Fully Leveraging Perception? Discover the Key to Smart Automation

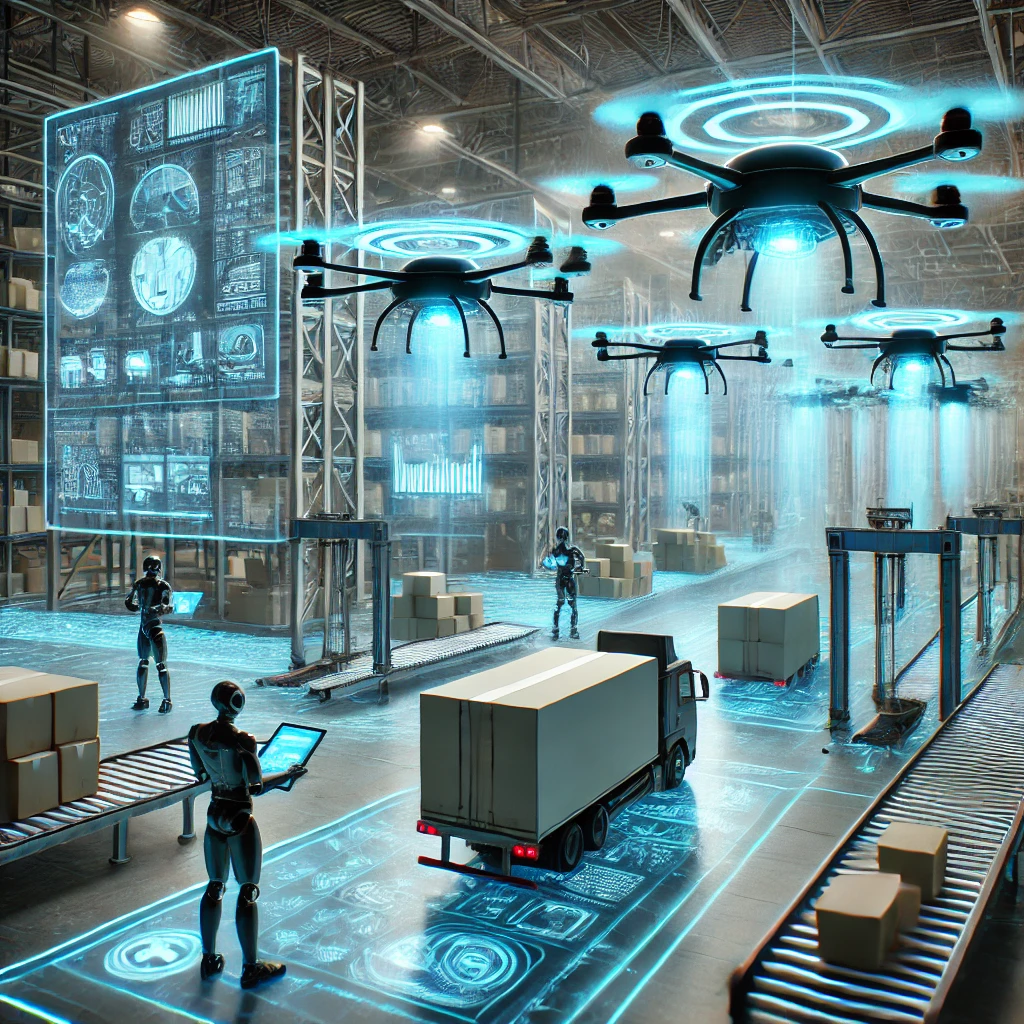

Picture this: You’re walking through your warehouse, and instead of seeing robots blindly following preset paths like zombies, you’ve got smart machines that actually understand their surroundings. They dodge obstacles without missing a beat, spot inventory issues before they become problems, and work alongside your team like they’ve been there for years.

This isn’t some far-off dream – it’s happening right now in warehouses across the world. Let’s talk about how perception technology is changing the game and what it really means for your operation.

What’s This “Perception” Thing All About?

Think of perception as giving your robots the ability to “see” and understand their environment, kind of like how humans use their eyes and brain to navigate the world. Instead of just following painted lines on the floor (so 2010!), these robots use cameras, sensors, and AI to actually understand what’s going on around them.

Here’s a real example: A traditional robot might stop dead in its tracks if someone leaves a box in its path. But a robot with good perception? It’ll spot the obstacle, figure out a new route, and keep right on working. That’s the difference we’re talking about.

Why Should You Care?

Let me share a quick story. A distribution center in Ohio was struggling with their traditional automation – constant stops, inventory mix-ups, the works. They upgraded to perception-enabled robots, and here’s what happened:

- Order fulfillment got 25% faster

- Accidents dropped by half

- They saved about $300,000 in their first year just by reducing errors

But it’s not just about the numbers. Their team actually prefers working with these smarter robots because they’re more predictable and responsive. As one warehouse manager put it, “It’s like the difference between working with a trained helper versus constantly watching a toddler.”

The Cool Tech Making This Happen

Let’s break down the tech without getting too nerdy about it:

The Eyes and Ears

These robots use a mix of:

- Cameras (like super-advanced versions of your smartphone camera)

- LIDAR (think radar, but with lasers)

- Various sensors that help them understand depth and distance

The Brains

This is where AI comes in. The robots aren’t just collecting data – they’re learning from it. Every day, they get a little bit smarter about:

- Finding the fastest routes

- Predicting where people will walk

- Spotting patterns in inventory movement

Making It Work in the Real World

If you’re thinking about upgrading your warehouse robots, here’s what you need to know:

Start Small, Think Big

Don’t try to revolutionize everything overnight. One warehouse I worked with started with just two perception-enabled robots in their busiest section. They learned what worked, fixed what didn’t, and then gradually expanded. Smart move.

Train Your Team

Your team needs to understand these robots aren’t just fancier versions of the old ones. They’re more like coworkers. The best implementations I’ve seen included the warehouse team in the planning from day one.

Watch the Numbers

Keep track of things like:

- How much faster orders are getting filled

- Where the robots are spending most of their time

- What kinds of problems they’re preventing

Common Headaches (and How to Avoid Them)

Let’s be real – this stuff isn’t always easy. Here are the main challenges people run into:

Cost Concerns

Yes, these systems are expensive. But consider this: One warehouse found that their perception-enabled robots paid for themselves in 14 months just through reduced errors and increased efficiency.

Technical Hiccups

The key is having good support. Make sure your vendor doesn’t disappear after installation. You want a partner, not just a supplier.

What’s Coming Next?

The future’s looking pretty exciting:

- Robots that can learn new tasks just by watching humans do them

- Systems that can predict and prevent bottlenecks before they happen

- Even better coordination between robots and human workers

Bottom Line

Here’s the truth: Warehouse robotics with advanced perception isn’t just a fancy upgrade – it’s becoming a necessity to stay competitive. But that doesn’t mean you need to rush in blind.

Start by assessing where perception could help most in your operation. Maybe it’s in picking, maybe it’s in inventory management. Find that sweet spot and build from there.

Remember: The goal isn’t to replace your team – it’s to give them smarter tools to work with. The warehouses that get this right aren’t just more efficient; they’re better places to work.

Ready to take the next step? Let’s talk about how you can start exploring perception technology in your warehouse. The future is already here – it’s just not evenly distributed yet.