Cobots vs Robots: What’s Shaping the Future of Work?

Introduction

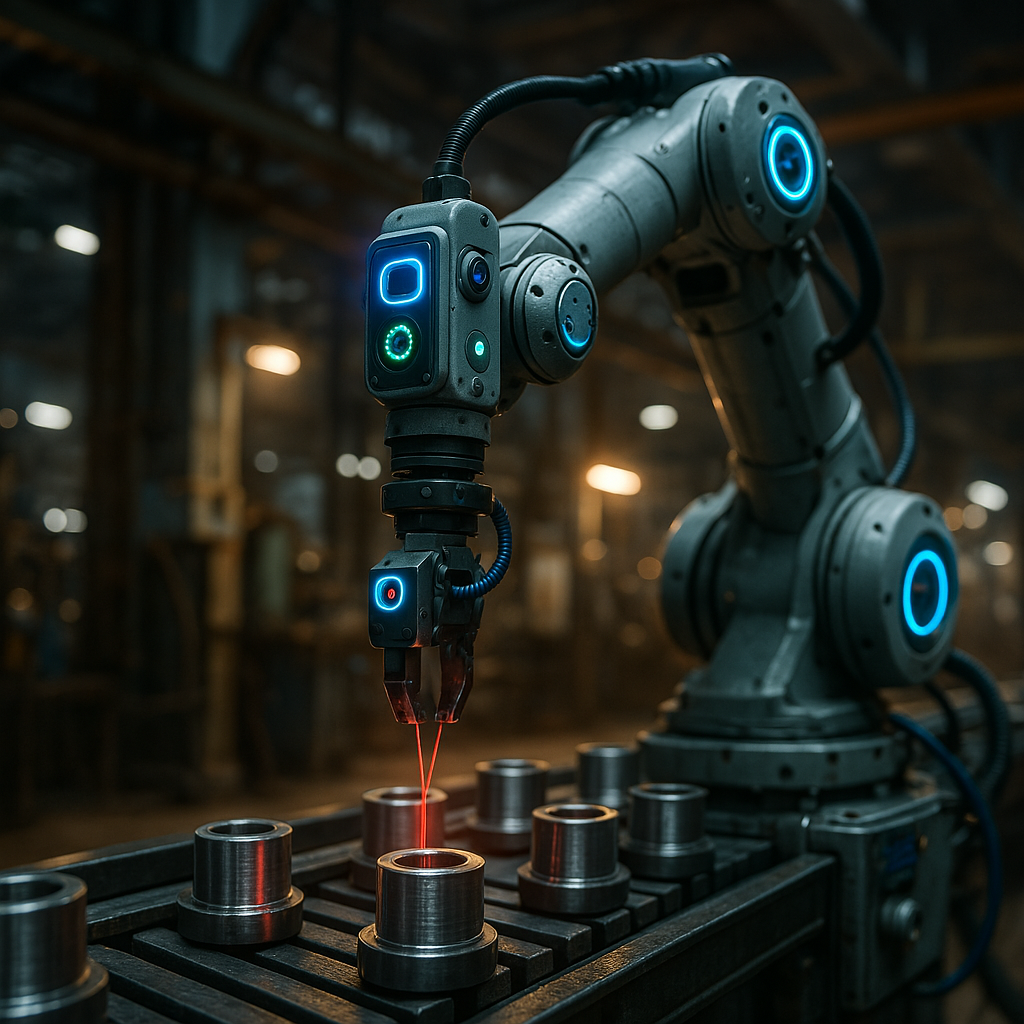

Robots in factories used to mean big machines in cages, doing repetitive tasks far away from humans. But now, a new type of robot is quietly redefining automation: the cobot.

Short for collaborative robot, cobots aren’t just efficient, they’re built to work with people, not replace them. They’re smaller, smarter, safer, and often more affordable than traditional industrial robots.

So here’s the big question: Are cobots the future, or just a niche tool in a growing robotics landscape?

Let’s break down the differences, strengths, and trade-offs between cobots and traditional robots. Whether you’re in manufacturing, logistics, or research, knowing which one fits your workflow could change how you think about automation entirely.

What Are Traditional Robots?

Traditional robots are what most people picture when they think of factory automation. They’ve been around for decades and usually have these traits:

- Large and fast

- Built for repetitive, high-volume tasks

- Often fenced off for safety

- Controlled via pre-programmed routines

- Used in automotive, electronics, and heavy manufacturing

These machines excel at consistency and speed. But they also require a lot of upfront investment, space, and supervision.

ALSO READ

What Makes Cobots Different?

Cobots, on the other hand, are designed to work safely alongside humans. Their defining features include:

- Built-in sensors and force limits to avoid injuries

- Compact design

- Easy to program (often with drag-and-drop interfaces or hand-guided training)

- Ideal for tasks that require human-robot collaboration

- Suited for small and medium-sized businesses (SMBs)

Instead of replacing workers, cobots help them. Think of them as robotic assistants rather than automated replacements.

Cobots vs Traditional Robots: Side-by-Side Comparison

| Feature | Cobots | Traditional Robots |

|---|---|---|

| Speed | Moderate | Very fast |

| Safety | Built for human interaction | Requires fencing and isolation |

| Programming | Intuitive, low-code | Complex, often requires experts |

| Flexibility | Highly adaptable | Designed for fixed tasks |

| Cost | Lower upfront cost | High installation and setup cost |

| Applications | Assembly, packaging, inspection | Welding, painting, machining |

| Ideal For | Small-medium businesses | Large-scale industrial settings |

Where Cobots Win

✅ Ease of Deployment

Cobots can be set up in days, not months. You don’t need a team of robotics engineers to get started.

✅ Agile Manufacturing

In industries where product lines change often, cobots offer quick reprogramming and redeployment.

✅ Worker Support, Not Replacement

Cobots handle tasks like screwdriving, box lifting, or repetitive inspections, freeing up humans for higher-value work.

✅ Lower Cost Barrier

Many cobots cost under $50,000, making them accessible to smaller firms looking to automate without major restructuring.

Where Traditional Robots Still Dominate

⚙ Speed and Power

Traditional robots can move faster and handle heavier payloads. In car manufacturing or large-scale electronics, they’re still essential.

🏭 High-Volume Consistency

If your operation involves thousands of identical tasks per hour, traditional robots are unmatched.

🔧 Specialized Tasks

Robotic welding, laser cutting, or precision machining require the force and precision of industrial-grade arms.

Safety: A Key Differentiator

Cobots are inherently safe. That’s their core design principle. They include:

- Force feedback to stop motion if contact is made

- Vision systems to detect nearby humans

- Speed and power limits based on risk assessment

Traditional robots, on the other hand, are often fast enough to cause serious injury. That’s why they operate in fenced-off areas with strict safety protocols.

Still, safety isn’t automatic. Cobots must undergo risk assessments too. But the built-in protections give them a major edge in mixed environments.

Industry Use Cases: Cobots in Action

🏭 Manufacturing

Small factories use cobots for pick-and-place, screwdriving, and component testing.

📦 Logistics

Cobots assist with sorting packages, scanning barcodes, and loading goods on conveyors.

💊 Pharma and MedTech

In cleanrooms, cobots handle repetitive lab tasks, reducing human contamination risks.

🍴 Food & Beverage

Cobots decorate cakes, sort produce, and package goods with speed and hygiene compliance.

So, Which One Should You Choose?

It depends on your needs.

- If you’re a large-scale manufacturer with strict speed and precision requirements, traditional robots still make sense.

- But if you want flexible automation that works with your team, cobots offer huge value.

In many cases, a hybrid setup, using both types, gives you the best of both worlds.

The Bigger Picture: Robots as Coworkers, Not Replacements

Cobots are part of a broader shift in how we think about machines. The goal isn’t to push humans out. It’s to build smarter workflows where robots assist, augment, and collaborate.

As labor shortages rise and production gets more personalized, companies that can integrate collaborative tech will gain speed and agility.

The future of work? It’s not robot vs human. It’s robot with human.

FAQs

1. What’s the main difference between cobots and traditional robots?

Cobots are designed to work with humans safely and flexibly. Traditional robots are faster and stronger but require isolated workspaces.

2. Are cobots safe to use in public or open environments?

Yes, most cobots are built with safety sensors and force limits. However, each deployment still requires a risk assessment.

3. Can cobots replace workers?

They’re more likely to assist than replace. Cobots handle repetitive or strenuous tasks, allowing humans to focus on creative or supervisory roles.

Call to Action

Ready to bring collaboration into automation?

Explore cobot options and see how your team can work with robots, not around them. The future of work is closer, and more collaborative, than you think.

Keywords (comma-separated)

cobots vs robots, collaborative robots, industrial automation, future of robotics, traditional robot comparison, cobot safety, cobot use cases, robotics in manufacturing, cobot vs industrial robot, human robot collaboration, robot coworker