Robotics in Construction: Smarter Builds and Safer Worksites

Introduction

The construction industry has always relied on human strength, skill, and coordination. Yet today, a new force is entering job sites, robotics. With smart machines taking on repetitive, hazardous, and time-sensitive tasks, robotics in construction is becoming a game-changer. These robots aren’t just about efficiency, they’re making building safer, faster, and more sustainable.

The Rise of Smart Construction Robots

Modern construction projects are more complex than ever. To meet tight deadlines and high safety standards, companies are turning to robotics. From autonomous bulldozers to robotic arms laying bricks, machines are transforming how infrastructure is built.

Key types of robots include:

- Robotic bricklayers that can lay thousands of bricks per day

- 3D printing robots for walls, panels, and structural elements

- Inspection drones that monitor progress from above

- Demolition robots used in hazardous or unstable buildings

- Surveying bots that create 3D maps in real time

Together, these systems reduce manual labor, limit injuries, and improve precision across all construction stages.

Boosting Productivity with Robotics

Time is money on a construction site. Robots can work longer hours without breaks or fatigue, allowing crews to operate around the clock. They also reduce bottlenecks by taking over repetitive or physically intensive jobs.

Examples include:

- Concrete robots that pour and level surfaces evenly

- Wall-painting drones that finish tasks in a fraction of the usual time

- Rebar tying machines that speed up foundation work

With robotics, construction managers gain more predictable timelines and better quality control.

Improving Site Safety with Automation

Construction remains one of the most dangerous industries worldwide. Robotics can help reduce risks by keeping humans away from:

- High altitudes or unstable scaffolding

- Heavy machinery operation zones

- Confined or toxic environments

For instance, autonomous bulldozers use GPS and sensors to clear land without operators inside. Similarly, demolition bots can tear down walls in damaged or fire-prone buildings, reducing the need for manual entry.

By offloading risky tasks, robots protect workers and reduce accident-related costs.

AI Meets Construction Robotics

Artificial intelligence plays a major role in construction robotics. AI helps machines:

- Learn from terrain data

- Adapt movement to different site conditions

- Optimize material usage in real time

- Detect structural flaws or deviations

For example, an AI-powered inspection drone can scan a building’s frame, identify weak points, and alert engineers instantly. Combined with computer vision, these smart bots provide data faster than traditional inspections.

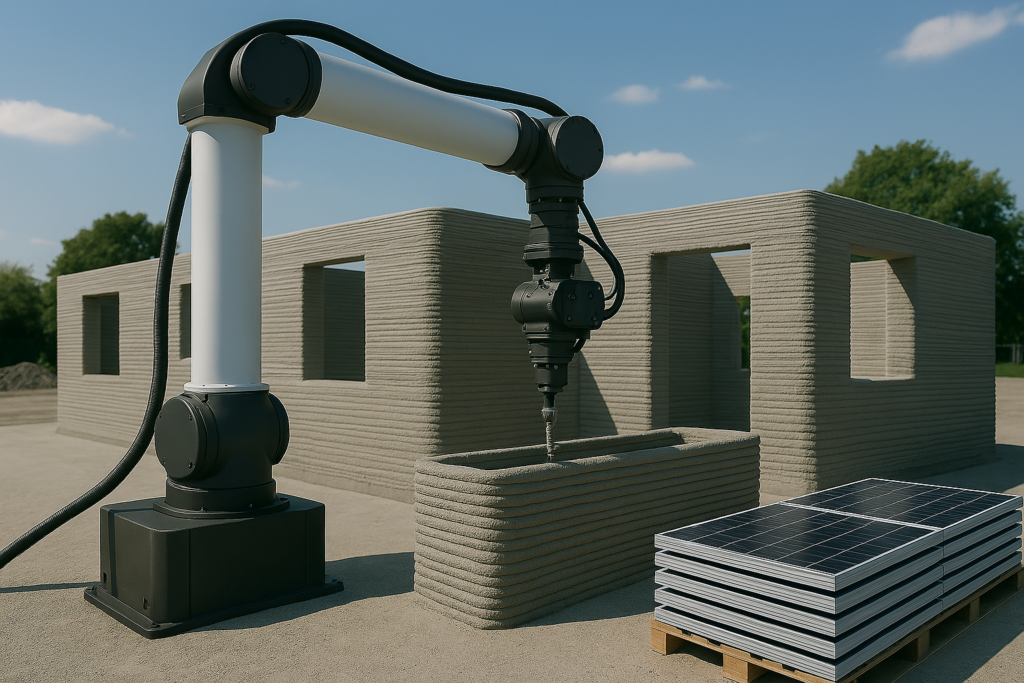

The Role of 3D Printing in Construction

3D printing is one of the most talked-about innovations in construction robotics. Using large-scale printers, entire walls and frames can be printed layer by layer using special concrete mixes.

Benefits include:

- Rapid construction of low-cost housing

- Waste reduction by using only required material

- Precise customization of shapes and structures

- Improved sustainability through local material sourcing

Some companies have already built homes, offices, and schools using robotic 3D printers, with fewer errors and lower emissions.

AI Image Prompt #2

Robots and Human Workers: A Collaborative Future

Rather than replacing jobs, construction robots are assisting skilled labor. Humans continue to:

- Monitor robots

- Program task flows

- Perform finishing work

- Solve unexpected problems on site

This synergy creates safer roles and allows workers to upskill into robotics management, digital modeling, or equipment diagnostics.

Training programs for construction tech are growing, giving workers new career paths in a high-tech industry.

Also Read

Barriers to Full Adoption

Despite the promise of robotics in construction, some challenges persist:

- High upfront costs for new equipment

- Integration difficulties with older workflows

- Regulatory uncertainty around autonomous machines

- Limited technical skill among current workforce

- Environmental unpredictability (weather, debris, terrain)

However, as more firms adopt robotics and see ROI benefits, these barriers are slowly breaking down.

Global Examples of Construction Robotics

Several countries are already pioneering robotics in construction:

- Japan: Using humanoid robots to assist with labor shortages

- Netherlands: 3D printing bridges and low-income housing

- USA: Startups developing robotic framing systems

- UAE: Printing entire villa complexes with autonomous systems

These examples show that robotics isn’t a future vision, it’s happening right now.

What’s Ahead for the Industry?

The future of robotics in construction includes:

- Autonomous project managers using AI for resource allocation

- Robot swarms that coordinate in real time

- Green robots that use sustainable materials and energy sources

- Remote-operated bots for disaster-zone rebuilding

- Wearable robotics (exosuits) to assist human laborers

Eventually, entire construction sites may run semi-autonomously, with humans guiding and innovating instead of lifting and digging.

Conclusion

Robotics in construction is more than just automation, it’s about creating safer sites, smarter workflows, and sustainable growth. With machines taking over dangerous and repetitive tasks, construction becomes more efficient and resilient. The shift is already underway, and those who embrace it now will lead the infrastructure revolution.

Ready to Explore More?

🏗️ Want to modernize your construction processes? Download our Robotics Integration Toolkit for Builders and discover how to future-proof your projects with smart machines.