Understanding the Science of Robotic Warehouse Navigation

Warehouses today are buzzing, complicated places with products, people, and machines. And right in the middle of all that activity, you’ll find autonomous mobile robots (AMRs), moving with amazing precision to fill orders and keep everything running smoothly. These robots might feel like something from a sci-fi movie, but their ability to navigate, find items, and steer clear of obstacles is actually based on a clever mix of computer science, math, and engineering.

The science behind how they get around is incredibly advanced, blending real-time data from different sensors with sophisticated algorithms to make sure they’re always operating at peak efficiency and safety.

In this article, let’s explore the core technologies and principles that allow these robots to move with such incredible accuracy, completely changing the world of warehouse automation.

What Is Robotic Warehouse Navigation?

Robotic warehouse navigation is the process by which autonomous robots move through storage environments to pick, transport, and deliver goods. Unlike conveyor belts or fixed automation, these robots think on the move. They combine sensors, algorithms, and AI to interpret their surroundings and plan efficient routes.

The main goals of robotic navigation include:

- Moving goods quickly without errors.

- Avoiding collisions with racks, conveyors, or workers.

- Adjusting in real time to changes in the environment.

- Supporting large-scale automated warehouse picking.

At its core, navigation is about perception, decision-making, and action—turning raw sensor data into precise movement.

The Core Science Behind Navigation Technology

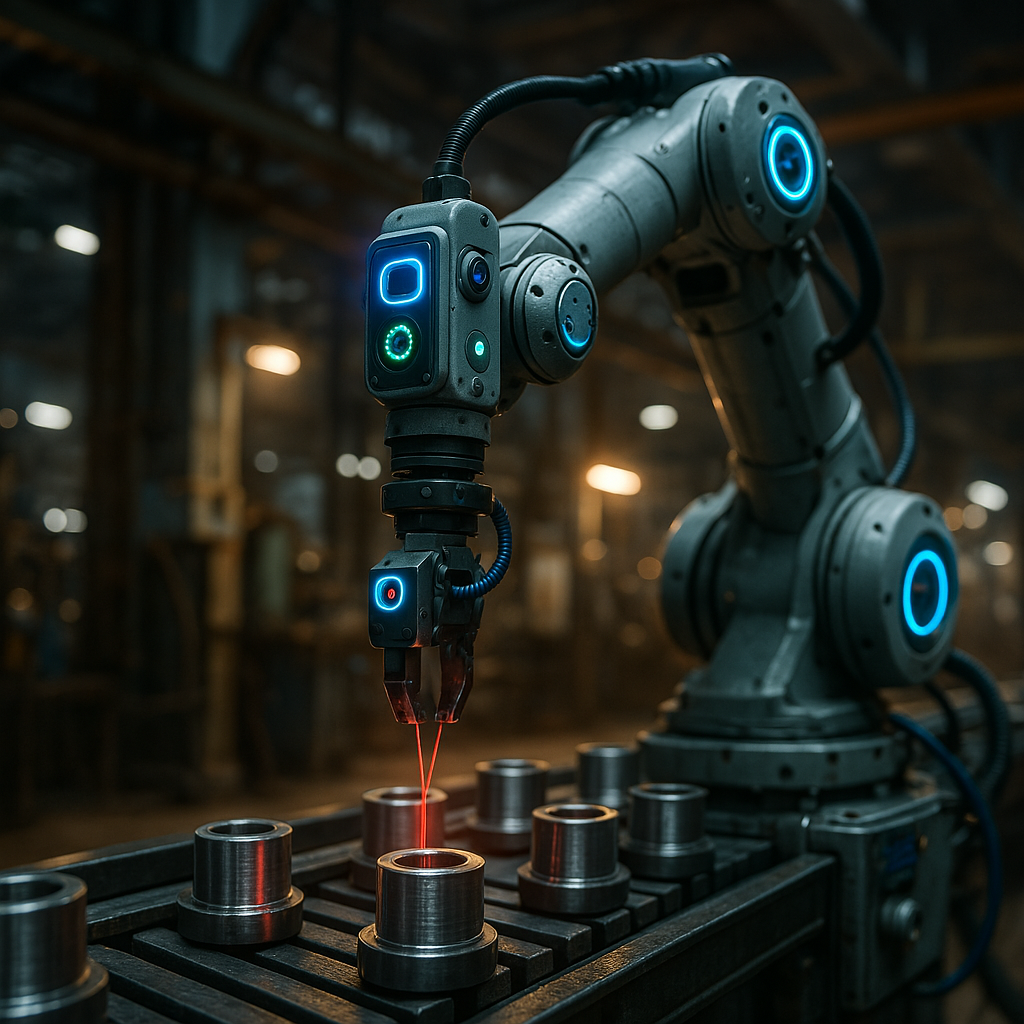

1. Sensors as the Robot’s Eyes and Ears

Robots rely on multiple sensors to perceive their surroundings. These include:

LIDAR: Projects lasers to map distances and create 3D models of the warehouse.

Cameras: Recognize barcodes, colors, and object shapes for accurate item identification.

Ultrasonic Sensors: Detect nearby obstacles in tight spaces.

IMUs (Inertial Measurement Units): Track acceleration and orientation to measure movement.

Together, these sensors allow robots to “see” and “hear” the warehouse.

Also See: Sensor Fusion Robotics: The Future of Robotic Picking Accuracy

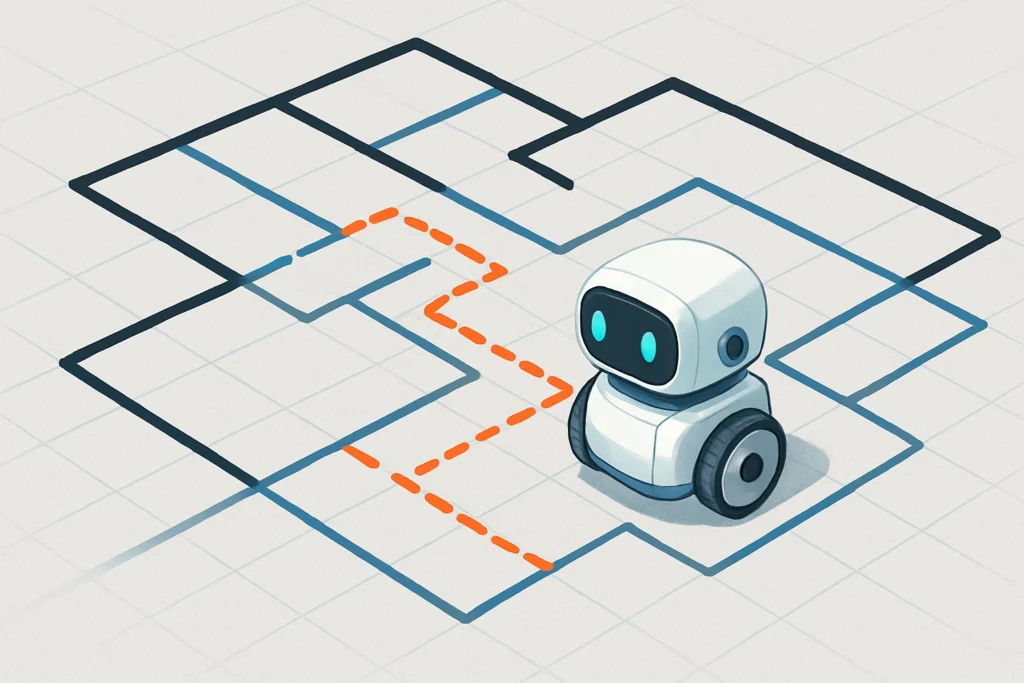

2. Pathfinding Algorithms

Robots don’t just wander. They follow optimized paths, thanks to algorithms like A* (A-star) or Dijkstra’s algorithm. These methods calculate the fastest and safest routes from one point to another, balancing speed with safety.

3. Simultaneous Localization and Mapping (SLAM)

SLAM is a breakthrough in AI robotics navigation. It enables robots to build maps of their environment while figuring out their own position within it. As warehouses evolve, robots update these maps in real time, staying accurate even in shifting layouts.

4. Machine Learning for Smarter Decisions

Over time, robots learn patterns: peak traffic areas, common obstacles, and high-demand zones. By applying AI robotics navigation, robots anticipate and adapt, becoming more efficient with every trip.

Why Navigation Is Critical for Warehouse Automation

Boosting Efficiency

Efficient navigation means faster order picking and smoother workflows. Robots that take optimal paths reduce congestion and increase throughput.

Enhancing Accuracy

Navigation is directly tied to robotic picking accuracy. A misplaced item or missed aisle can disrupt entire shipments. With precise movement, robots consistently reach the right spot at the right time.

Supporting Scalability

As order volumes grow, more robots can be added seamlessly. Because navigation systems are decentralized, they scale without creating bottlenecks.

Improving Safety

Navigation technology reduces collisions with racks, equipment, or people. This makes warehouse automation technology safer for both machines and workers.

Types of Robotic Navigation in Warehouses

1. Fixed Path Navigation

Early robots followed fixed magnetic strips or QR codes on floors. While reliable, this system lacked flexibility when layouts changed.

2. Free Navigation with SLAM

Modern robots rely on SLAM and AI pathfinding. They move freely without fixed paths, adapting instantly when aisles or racks are rearranged.

3. Hybrid Systems

Some warehouses combine fixed routes for repetitive tasks with free navigation for complex ones. This balances stability and adaptability.

How Robots Achieve Pathfinding Accuracy

Dynamic Mapping: Updating layouts in real time prevents robots from getting “lost.”

Obstacle Avoidance: Robots detect humans, forklifts, or unexpected objects and reroute instantly.

Traffic Control: Advanced robotics logistics systems coordinate multiple robots to avoid traffic jams.

Redundancy: Multiple sensors cross-check information, ensuring one faulty reading doesn’t cause errors.

This combination of redundancy and intelligence guarantees robust performance in high-pressure environments.

The Role of AI in Navigation Technology Robotics

AI takes robotic navigation beyond simple movement:

- Predictive Pathing: Anticipating traffic based on time of day or order flow.

- Adaptive Speed Control: Slowing down in crowded areas, speeding up in open aisles.

- Collaborative Routing: Multiple robots sharing data to optimize warehouse-wide efficiency.

- Error Reduction: AI detects anomalies, such as missing items, and adjusts accordingly.

Benefits of Robotic Warehouse Navigation

Operational Advantages

- Higher Throughput: More orders processed per hour.

- Lower Costs: Reduced reliance on manual labor.

- Reliability: Consistent accuracy, even during peak loads.

Strategic Advantages

- Flexibility: Easy to adapt to new product lines or layouts.

- Sustainability: Smarter routing reduces energy consumption.

- Competitive Edge: Faster and more reliable fulfillment enhances customer satisfaction.

Challenges in Robotic Navigation

Complex Environments: Busy warehouses create unpredictable conditions.

Integration with Legacy Systems: Older inventory software may not sync with advanced robotics logistics systems.

High Upfront Costs: Sensors and AI-powered robots require investment.

Data Overload: Robots generate massive streams of navigation data that need advanced warehouse automation technology to manage.

Despite challenges, most warehouses achieve ROI within a few years due to improved efficiency and reduced errors.

FAQ: Robotic Warehouse Navigation

How do warehouse robots know where they’re going?

They use sensors, AI algorithms, and mapping systems like SLAM to calculate and adjust paths.

Are robots replacing human pickers?

Not fully. Robots handle repetitive navigation and transport, while humans focus on complex tasks.

What happens if a robot’s sensors fail?

Redundant systems ensure that backup sensors take over to prevent accidents or errors.

Can navigation robots work in small warehouses?

Yes. Modern systems are scalable and can be tailored to fit small, medium, or mega-warehouses.

How does robotic navigation impact sustainability?

By optimizing routes and reducing wasted energy, navigation systems lower overall carbon footprints.

Conclusion

From automated warehouse picking to full-scale robotics logistics systems, robotic warehouse navigation significantly boosts efficiency, safety, and scalability. As warehouses continue to get smarter, navigation will remain the most critical factor driving the effectiveness and innovation of warehouse robotics.

The underlying science behind these systems reveals a simple truth: robots aren’t just moving things; they’re completely changing how the global supply chain operates.